Recently, the heat wave has swept across the globe, and swimming has become the best sport in such high temperature weather. Unlike general high bay lighting, indoor swimming pool lighting has more stringent requirements on LED high bay light. In order to provide safe, comfortable and efficient lighting, a variety of complex factors need to be considered.

Safe Lighting

The top priority is safety. Due to the presence of chlorine in the swimming pool environment, long-term exposure to corrosive chlorine will cause corrosion to general luminaires, resulting in malfunction of the indoor swimming pool lighting function or even partial corrosion of the LED high bay light.

The humidity of the swimming pool is extremely high, up to 50-60%. In special conditions, this value can reach 80% or more. If the humidity is too high, it is easy to affect the metal. In the high humidity environment, it is recommended to use the following material: cast iron, stainless steel, brass, aluminum, zamark, chrome, composites, plastic, PVC. At the same time, the luminaires should have a high degree of protection rating to prevent water vapor from affecting the normal operation of LED chips and driver.

The LED high bay light must be able to maintain normal and stable lighting in the extraordinarily corrosive environment of the swimming pool. In addition to the high degree of protection required, the luminaires also need to have the function of preventing chlorine corrosion to ensure safe lighting.

The corrosion-resistant materials and unique structural design make sure that Compact I LED high bay light is the top performer in swimming pool.

The heat sink adopts aluminum material with excellent anti-corrosion performance, and the surface is sprayed with epoxy, which further increases the corrosion resistance of Compact I and can prevent the corrosion of chloride at the same time.

These chemicals are commonly used in swimming pools, acidic and corrosive chlorinating agents, alkaline disinfectants, and weakly acidic algicides, for cleaning and disinfecting, which cause extraordinary corrosion to the LED high bay light.

As an anti-corrosion material, epoxy resin has the characteristics of compactness, water resistance and high chemical stability. The cured epoxy resin system has excellent alkali resistance, acid resistance and solvent resistance. Luminaires that sprayed with epoxy resin can keep well operating in the very harsh corrosive environment of the pool.

The unique structure of Compact I greatly reduces direct glare, and the nano coating around the LED chips ensures the light more uniform. 90° frosted cover further reduces glare.

· Avoid halos, and have no shadow effect, providing perfect illumination.

The twill design of the cover can effectively reduce the glare value.

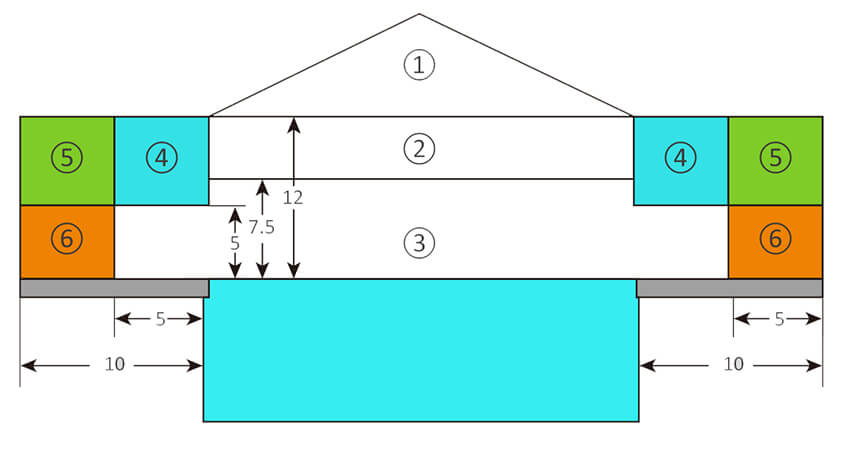

The following diagram adapted from the 2014 NEC Handbook, Article 680 on accepted luminaire placement and restrictions.

The following table refers to the Illuminating Engineering Society of North America RP-06-01 for Sports Recreational Area Lighting.

|

Class |

Occasion |

Water Surface(lux) |

Deck(lux) |

Water Surface Uniformity Max:Min ratios |

Deck Uniformity Max:Min ratios |

|

Class I |

Professional |

807 |

538 |

1.7:1 |

2.5:1 |

|

Class II |

Collegiate |

538 |

215 |

2.5:1 |

4:1 |

|

Class III |

Intermediate |

323 |

108 |

3:1 |

4:1 |

|

Class IV |

Recreational |

323 |

108 |

4:1 |

4:1 |

Tel:+86-755-29435812

Fax:+86-755-26755760

Email:sales@yahamlighting.com

Address: 5F, Tower A, Haina Baichuan Headquarters Building, No.6 Baoxing Road, Baoan District, Shenzhen, China.

Copyright © 2024 Yaham Optoelectronics Co.,Ltd. All Rights Reserved. Privacy Policy

Yaham Lighting is a professional LED Flood Light, LED Street Light, LED High Bay Light manufacturer, we are looking for Sole Distributors/Agents worldwide.